The agricultural industry is undergoing a rapid transformation, driven by the need for increased efficiency, reduced labor costs, and sustainable practices. Automation is at the heart of this evolution, with machinery increasingly relying on sophisticated control systems and precise movements. A critical component in nearly all automated agricultural machinery is the gear motor. These tireless workhorses convert electrical energy into mechanical motion, providing the torque and speed required for a vast array of tasks – from operating harvesting equipment and spraying systems to controlling robotic arms and precision planting tools. Successfully integrating gear motors into automation upgrades, however, requires careful consideration of selection and matching to ensure optimal performance, reliability, and longevity. This guide will delve into the key aspects of gear motor selection and matching for agricultural machinery automation, providing insights for engineers, technicians, and farmers looking to enhance their operations.

Understanding the Role of Gear Motors in Agricultural Automation

Before diving into selection criteria, it’s crucial to understand the diverse roles gear motors play. Agricultural automation doesn't have a one-size-fits-all approach; each application demands specific motor characteristics. Common applications include:

Harvesting Equipment: Powering cutting mechanisms, conveyors, and sorting systems.

Spraying Systems: Controlling pump speed and nozzle operation.

Tractor Implement Control: Actuating plows, cultivators, and planters.

Robotic Systems: Providing precise movements for picking, pruning, and monitoring.

Material Handling: Operating conveyors and automated storage solutions.

The demands of each application vary greatly. A harvesting machine needs high torque at relatively low speeds, while a robotic arm might require high speed and precision. Ignoring these nuances can lead to underperformance, premature wear, and costly repairs.

Key Parameters for Gear Motor Selection

Choosing the right gear motor requires evaluating several key parameters:

Torque Requirements: This is arguably the most important factor. The torque needed depends on the load the motor must overcome – consider the weight of objects being moved, the resistance of the mechanism, and the acceleration/deceleration requirements. It’s always wise to add a safety factor (typically 20-30%) to the calculated torque to account for unforeseen loads and operating conditions. Over-sizing a motor isn't always best; it can lead to inefficiency.

Speed (RPM): The required speed is directly related to the application’s function. High-speed applications, like spray nozzles, require high RPMs, while low-speed applications, like powering a large conveyor belt, require low torque at high RPMs. Confirm the RPM requirements based on the mechanical design.

Gear Ratio: The gear ratio determines the relationship between input speed and output speed/torque. A higher gear ratio reduces speed while increasing torque, and vice versa. Selecting the appropriate gear ratio is crucial for matching the motor’s characteristics to the application’s needs. Calculations should consider the desired output speed and the input motor speed.

Power: Power (measured in Watts or Horsepower) is a function of torque and speed. Ensure the motor's power rating is sufficient to handle the workload without overheating or stalling. Consider the duty cycle (how frequently the motor operates) when determining power requirements.

Efficiency: Higher efficiency translates to lower energy consumption and reduced operating costs. Look for gear motors with high efficiency ratings, especially if running on renewable energy sources.

Environmental Considerations: Agricultural environments are harsh. Choose gear motors with appropriate IP (Ingress Protection) ratings to protect against dust, water, and other contaminants. Consider motors designed for outdoor use and resistance to extreme temperatures.

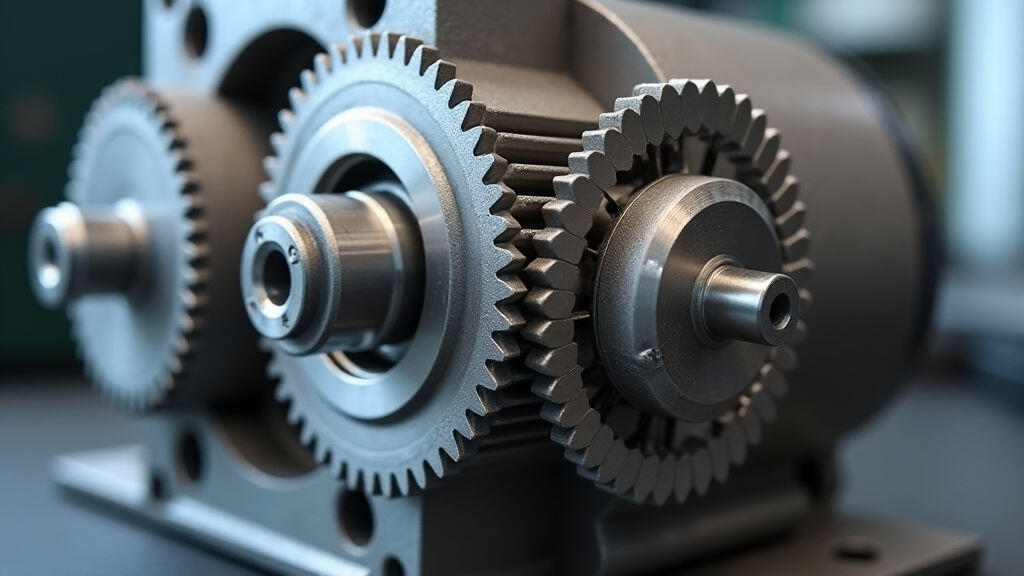

Motor Type: Different gear motor types offer varying advantages. Common types include:

Worm Gear Motors: Offer high gear ratios in a compact package, ideal for applications requiring high torque and low speed.

Spur Gear Motors: Efficient for moderate torque and speed requirements.

Planetary Gear Motors: Provide high torque density and compact designs, suitable for applications where space is limited.

Matching the Gear Motor to the Application

Simply selecting a motor based on parameter values isn't enough. Proper matching is crucial for optimal performance:

Load Characteristics: Analyze the load profile – is it constant, variable, or intermittent? This information is crucial for sizing the motor and selecting the appropriate gear type.

Control System Integration: Ensure the gear motor is compatible with the selected control system (PLC, microcontroller, etc.). Consider the communication protocols and feedback mechanisms required for precise control.

Mounting and Space Constraints: Physical dimensions are essential, especially in space-constrained applications like robotic systems. Select a motor with a suitable mounting configuration and compact design.

Operating Environment: The operating conditions – dust, moisture, temperature extremes – influence the choice of motor enclosure, lubrication, and materials.

Future Trends and the Role of Automation

The trend towards greater automation in agriculture is accelerating. As machinery becomes more sophisticated and features more advanced control systems, the demand for high-performance gear motors will continue to grow. Key future trends influencing gear motor selection include:

Increased Use of Brushless DC (BLDC) Motors: BLDC motors offer higher efficiency, longer lifespan, and improved control compared to traditional brushed motors.

Integration of Sensors and IoT: Gear motors are increasingly being integrated with sensors and IoT devices to provide real-time data on performance and condition.

Development of Smart Gear Motors: These motors feature built-in diagnostics and predictive maintenance capabilities, reducing downtime and improving reliability.

Focus on Energy Efficiency: Continually improving gear motor efficiency will decrease operating costs and environmental impact.

Conclusion

Gear motors are undeniably essential components for achieving the full potential of agricultural machinery automation. Selecting and matching the right gear motor requires a thorough understanding of application requirements, key parameters, and future trends. By carefully considering torque, speed, gear ratio, power, efficiency, and environmental factors, farmers and engineers can ensure optimal performance, reliability, and cost-effectiveness. As automation continues to revolutionize the agricultural landscape, the demand for advanced and intelligent gear motor solutions will only intensify. Investing in properly selected and maintained gear motors is not just a mechanical consideration; it’s an investment in the future of sustainable and efficient agriculture. The integration of smart motor technologies and proactive maintenance strategies will be paramount in realizing the full benefits of automation and ensuring the long-term success of agricultural operations.

Leave A Reply

Your email address will not be published. Required fiels are marked